Telephone: 400-007-7724

Fax: +86 512-82175788

Postcode: 215300

E-mail: info@tmmotion.com

Address: Building 2,No.1299 Fuchunjiang Road,Development Zone Kunshan City Jiangsu Province, China.

In recent years, the booming market for new energy vehicles has led to a rapid increase in the demand for lithium battery equipment, because lithium battery is one of the core components of new energy vehicles, accounting for 40% of the total production cost of new energy vehicles.

Based on this, many people are interested in lithium battery, want to know how lithium battery is "born" , this issue, the small series simply explained:

Lithium battery main production process (successively production process) include: positive and negative plate, assembly and conversion. The positive and negative levels are divided into homogenization, coating, rolling, cutting, this process is all in a fully automatic closed system to maintain the manufacturing of green and safe, assembly is divided into stamping, lamination, welding, heat sealing, injection fluid; It is divided into aging, charging and discharging, vacuuming and testing and sorting, that is, a lithium battery from scratch, to say the least, covering dozens of processes.

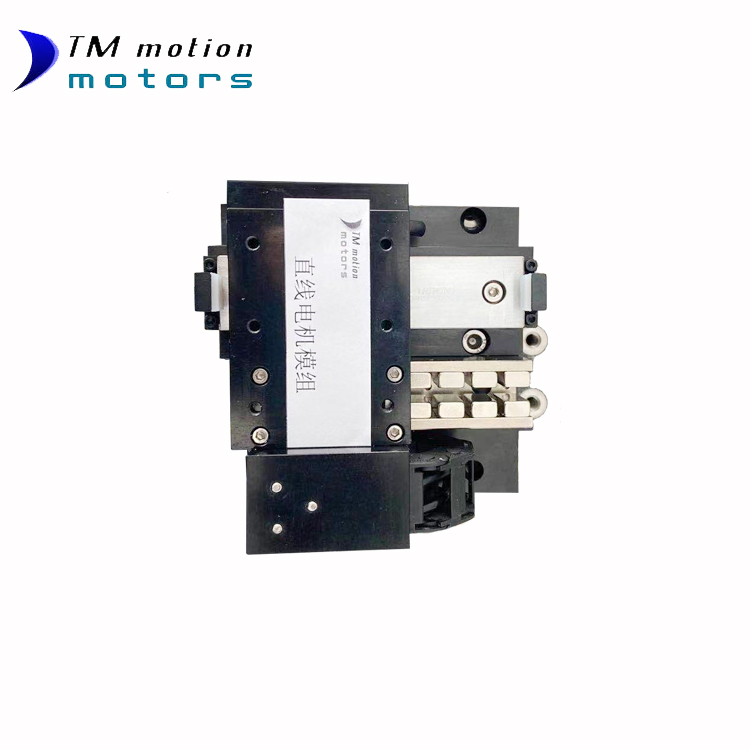

Among them, the small series should focus on the laminating process, which is currently accomplished by an advanced automatic laminating machine, and the linear motor module laminating machine is one of the more mainstream automatic laminating machines, the laminating machine of Linear Motor module uses the mechanical arm to take up the laminating film alternately in the middle position of the two pick-up electrode materials while moving left and right, at the same time, it completes the Z-SHAPE laminating deflection of the diaphragm while moving left and right, thus realizing the laminating assembly of the whole electric core repeatedly The mechanical arm adopts Linear Motor module to realize high-speed, steady and accurate movement, the computer rectifying mechanism controls the uniformity of discharging, and the CAM divider is used to convert different electrode materials.

Kunshan Tongmao Electronics Co. , Ltd. . Deep Tillage Linear Motor module field more than 10 years, Tongmao linear motor module is now widely used in all walks of life, to help China's intelligent manufacturing.

The article was originally written by www.tmmotion.com in Kunshan, China. Please quote the source.