Telephone: 400-007-7724

Fax: +86 512-82175788

Postcode: 215300

E-mail: info@tmmotion.com

Address: Building 2,No.1299 Fuchunjiang Road,Development Zone Kunshan City Jiangsu Province, China.

In recent years, 3d printing technology has rapidly penetrated all walks of life, playing an important role in many fields including architecture, electronics, biomedicine, aerospace and so on.

Compared to other fields, the application of 3D printing technology in the aerospace field is not yet widespread, belongs to the exploration stage, in the near future, x-Bow, a company that specialises in 3D printed rocket launch systems, has made a breakthrough in 3d printed solid rocket motors. It is reported that rockets are divided into solid rockets and liquid rockets according to the fuel used by the engine. Solid rockets have the advantages of high thrust, convenient launching and simple structure. In order to optimize the shortcomings of solid rocket, X-Bow uses modern technologies such as 3d printing, digital engineering and parametric design to optimize the structure of solid rocket motor and break through the bottleneck of existing technologies.

When it comes to 3D printing, it is not an independent technology. Its development and popularization can not be separated from the support of linear motor driving technology, it has been introduced into 3d printing equipment by many device intelligence manufacturers, and has achieved the effect of Fast Response and smooth operation.

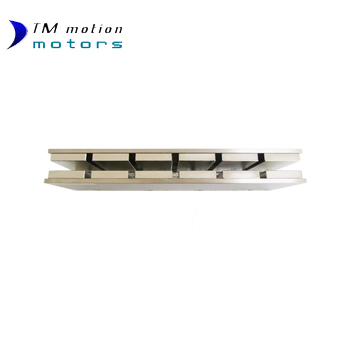

Kunshan Tong Mao Electronics Co. , Ltd. self-developed and self-marketing linear motor products, including no core U Slot and plate with iron core two categories, are using European and n technical standards and processing technology, favored by equipment manufacturers.

The article was originally written by www.tmmotion.com in Kunshan, China. Please quote the source.