Telephone: 400-007-7724

Fax: +86 512-82175788

Postcode: 215300

E-mail: info@tmmotion.com

Address: Building 2,No.1299 Fuchunjiang Road,Development Zone Kunshan City Jiangsu Province, China.

Pencil is one of the common stationery supplies, from the writing and drawing of the lower grade students to the creative design of artists, can not be separated from pencil.

When we buy pencils, we often see the word“H” and“B” written on the pencil package. What's the difference between a pencil with“H” and a pencil with“B”?

1. Different degrees of softness“H” means a hard pencil, “B” means a soft pencil, and“HB” means a pencil with moderate softness and hardness.

2. The handwriting color is different. The handwriting color of class H pencil is not obvious. The handwriting color of class B pencil is very black. The handwriting color of class HB pencil is moderate black.

3. Scope of application different class H pencils are suitable for objects with relatively hard or rough interfaces. Class HB pencils are suitable for writing (writing) in general. Class B pencils are good for drawing (especially drawing) , where the 2B pencil is used to fill in machine-readable cards, such as answer sheets.

Speaking of pencils, by the way the production of pencils, and linear motor in the production of pencils in the application. Pencil production is divided into four steps: 1, lead production. The workers mixed graphite powder, clay and water, poured into a blender, fully stirred the liquid squeezed into the machine, the machine will automatically spit out long strips of refill; The strips are then dried and cut, then baked at 815 degrees centigrade, and the dried cores are placed in hot oil or paraffin wax, in order to make these refills more smooth and waterproof. 2. Outside the stick making. A typical pencil factory uses cedar wood, which is cut into small pieces, each of which is about half the thickness of a pencil-about 0.2 inches, or 0.5 centimeters And then you cut these boards, and you cut a groove in the middle, and the planks that have grooves are divided into two groups, and one of the groups is sent to the next machine, and then you put glue on the groove, another group was cut and refills meet. 3. The glue-coated plank and the graphite-lined plank are pressed together, and the pencil is made! 4, then according to the needs of spray painting color, print labels. The linear motor-supported cutting equipment is used for cutting pencil lead and pine; the linear motor-supported gluing machine for gluing groove; The marking machine with linear motor is used for marking logo and model information...

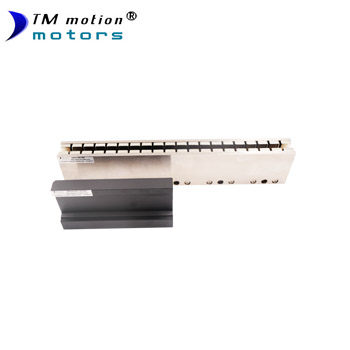

Kunshan has been cultivating the field of linear motors for more than 10 years. The main types of linear motors produced by Tong Mao are iron-free U-shaped groove and flat plate with iron core.

This article was originally published by Kunshan Tong Mao Electronics Co. , Ltd. (www.tmmotion.com ) .